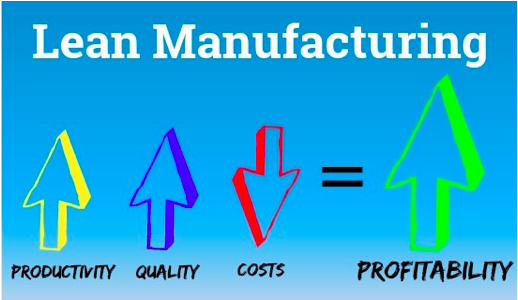

Lean manufacturing principles and digital process automation have the same goals and objectives which are to reduce waste, boost efficiency and enhance customer satisfaction. To achieve these, both these approaches focus on removing non-value activities and cutting down wastage, while maintaining the same product standards. In this article, we focus on how digital process automation can help firms realise lean manufacturing principles and the impact of these principles on the automation market.

1. Reduce waste

Digital process automation helps firms to reduce waste, one of the fundamental principles of lean manufacturing. Automation sets up very tight tolerance and quality levels, which sends indications if the required levels are not met. Thus, it eliminates reworking of products and minimising the amount of scrap produced.

Also, since automated systems are designed to perform multiple operations at one go, finished products can be directly delivered to storage units without any human intervention. This brings efficiency into the entire supply chain.

2. Maintain levelling production

Automation brings Internet of Things (IoT) into play which greatly reduces dependence on humans to maintain the same production levels every day irrespective of the happenings. This aligns with the lean manufacturing principle of Heijunka, a Japanese word meaning levelling production.

Through digital automation and IoT, firms will get accurate production report, which will help them set daily target, thus keeping production consistent and avoid rushing to meet any particular order. At the same time, enterprises can have a backup in case of any contingency.

3. Remove human error

Digital process automation not only identifies human errors but completely removes them from the equation. Aligning with the principle of Jidoka, process automation sets up machines to do task automatically, rather than making humans check defects or errors of every product.

Whenever an error is detected, an alarm is raised thereby making everyone aware of the situation. This helps in timely intervention, take the necessary steps and ensure the defective product is either removed or serviced to eliminate chances of a product recall. While minute errors may miss the human eye, it’s next to impossible to bypass the automation system.

Impact of lean manufacturing principles on digital process automation market

Lean manufacturing is becoming one of the best manufacturing businesses in India Worldwide companies are looking forward to bringing down the cost of production, eliminate waste and streamline manufacturing processes with an accurate view of its workforce and lean manufacturing tools and principles. These can be achieved only with process automation, which is not only a modern-day need but also a necessity.

It is because of this necessity that firms across the globe are developing process automated systems which align themselves with lean manufacturing principles and tools. This development is likely to bolster the process automation market which is expected to register a CAGR of over 7.23% [1] during the 2019-2024 period, with the number of IoT connected devices expected to reach 51.11 [2] billion by 2023.

While humans would still be required to operate these connected devices, their growing numbers in the coming days would boost the need for automated systems in place which can operate them with minimal human intervention.

The final word

As businesses become more competitive in the coming days, companies need to come up with top-class products while minimising costs and eliminating waste. This can be achieved by integrating lean manufacturing tools and digital process automation into operations which will help companies not only simplify the entire process but also achieve end objectives with utmost ease, thus improving bottom-line revenues in the long run.

Also, in evolving economies of the globe which often face the dearth of skilled workforce and look forward to adopting lean manufacturing tools to save costs and cover gaps, digital process automation is expected to witness an increasing adoption.